Established in 1982, CONTOUR FINE TOOLING has grown to become the premier supplier of single crystal diamond tools around the world.

Some of the services Contour can provide for you.

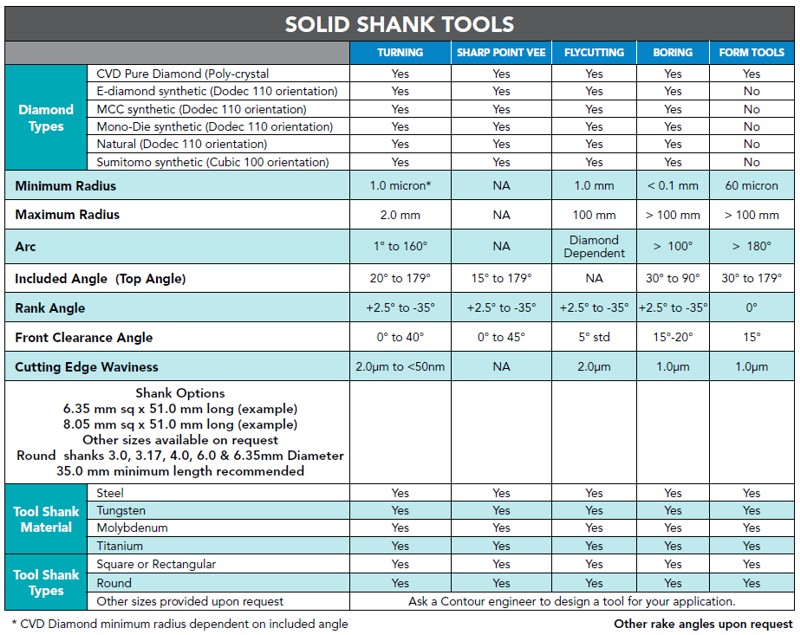

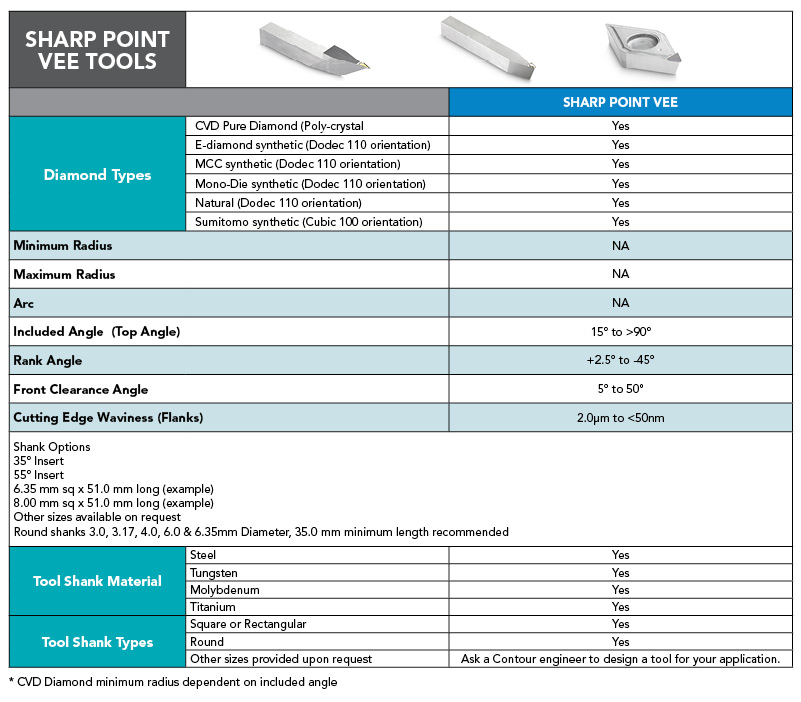

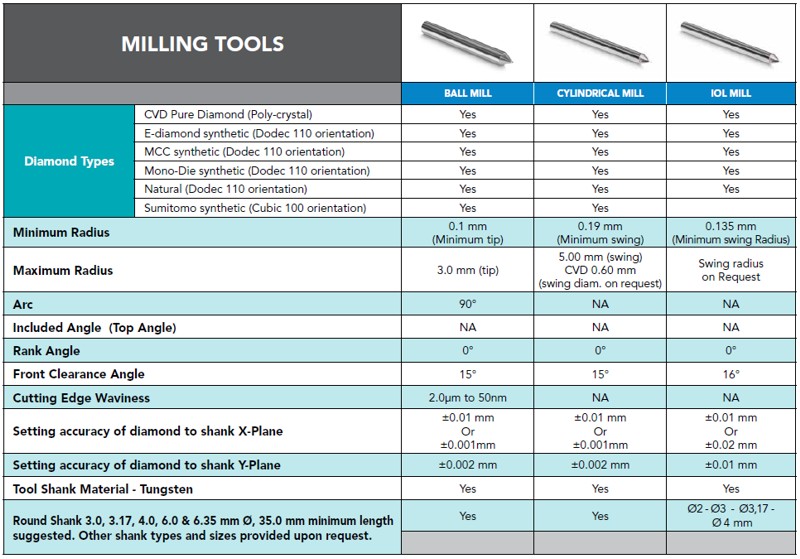

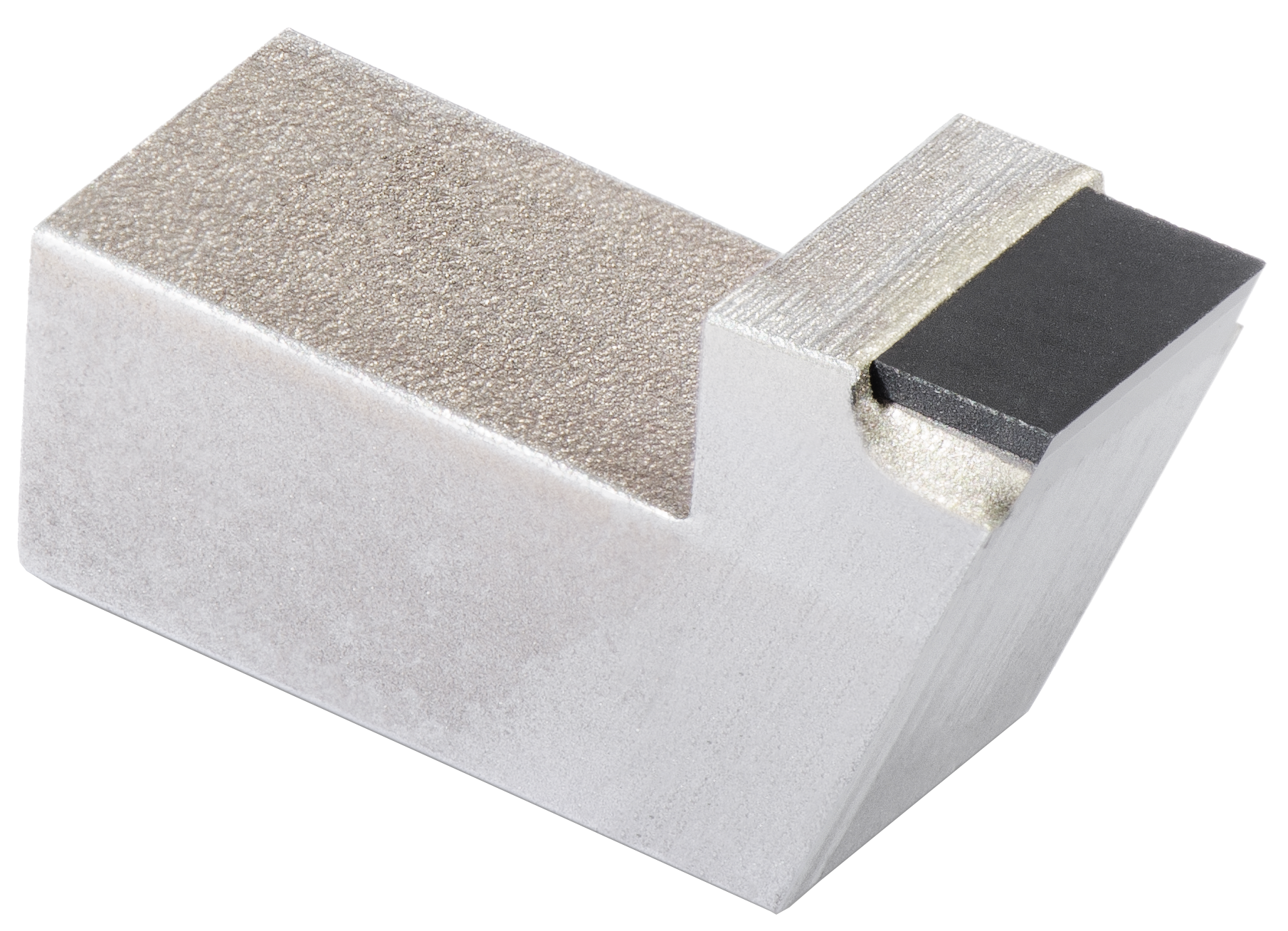

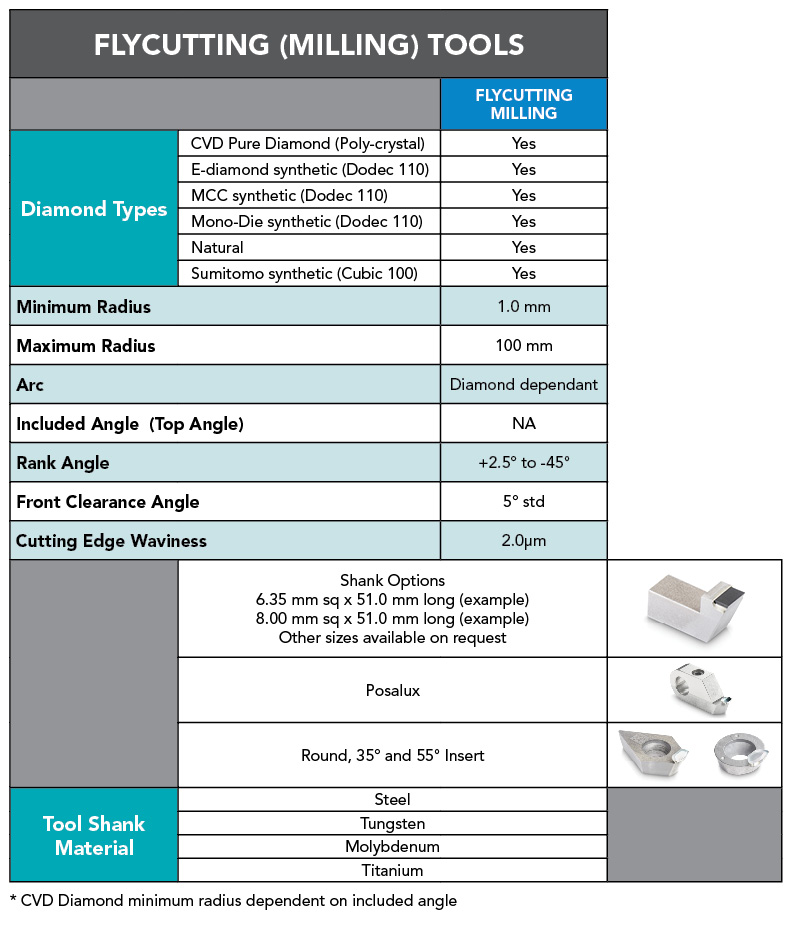

- Cutting tools on solid shanks or inserts

- Tool radius from 100mm radius down to 1.0 micron

- Tools to machine non-ferrous materials, inferred optics, and steel with the assist of an ultrasonic tool post

- Non-controlled waviness cutting edges

- And controlled waviness cutting edges to 50nm or better over the full arc

- Cutting edge arc up to 180 degrees

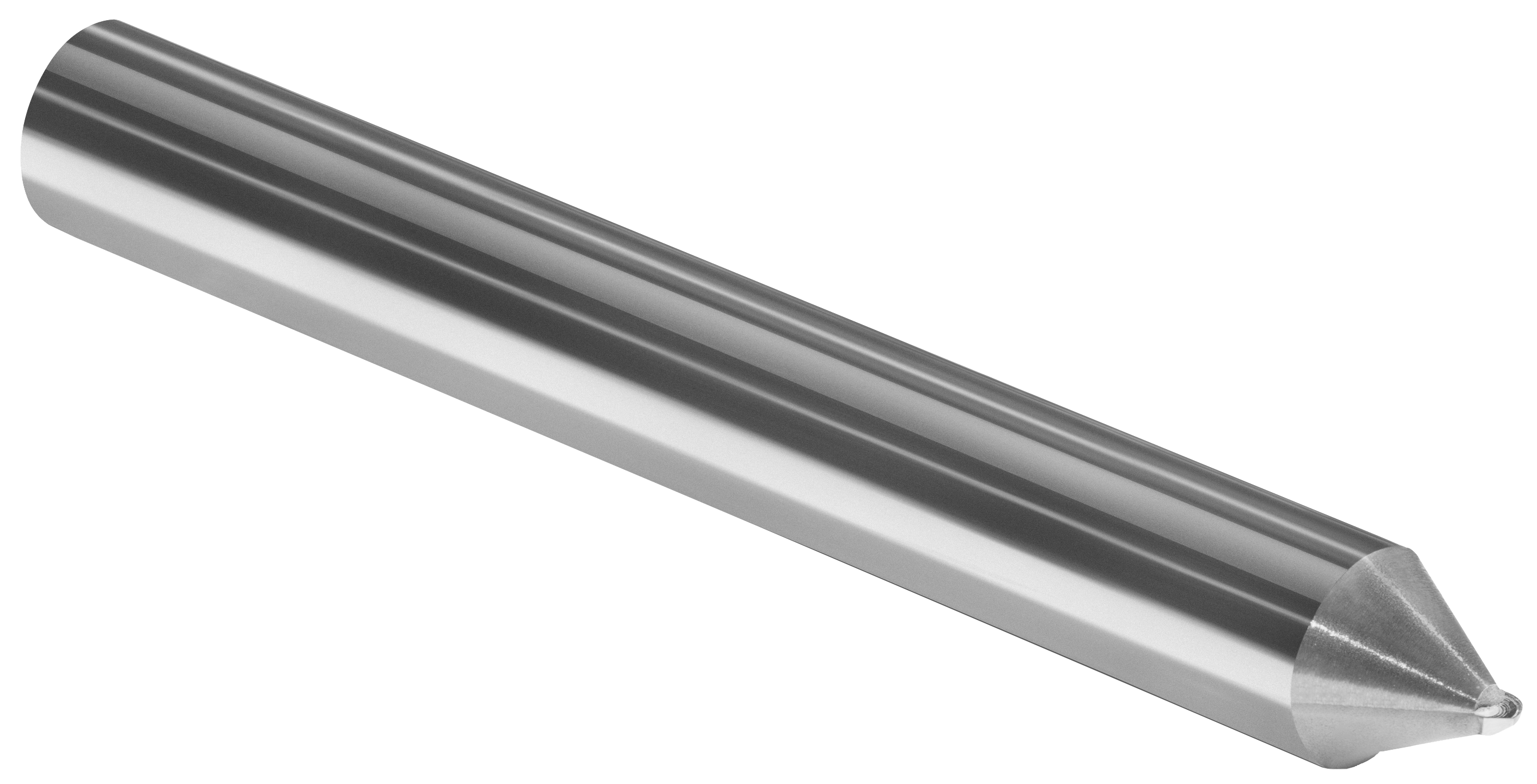

- Milling Tools provided with a radius or cylindrical or custom forms (in CVD) are available from Contour

- Single crystal natural and synthetic diamond and CVD pure diamond as a superior alternate to PCD diamond tools

- Tool holders to fit your specific machine and application set up