Superior nickel coating for workable nickel

CZL Tilburg has more than 25 years experience in electroless and electrolytic nickel phosphorous for a wide range of industries. We offer a special nickel phosphorous coating for optical and technical applications.

Our personnel have many years experience in the application of workable diamond nickel phosphorous (NiP). They have a broad knowledge of the requirements customers must comply with in relation to such coatings.

Flawless nickel coatings

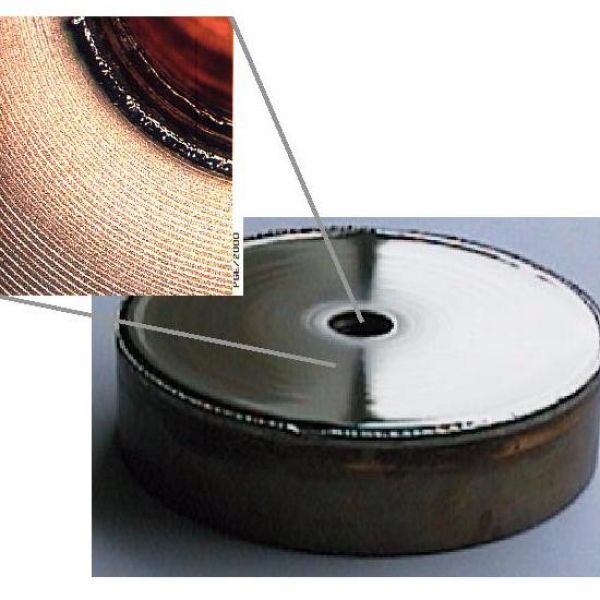

The process specialists of CZL Tilburg have developed both a electroless and a galvanic nickel phosphorous coating to overcome the existing limitations of electroless nickel-plating processes. Traditional processes cannot apply coatings thicker than 200 microns without the risk of pitting and skip plating. Using SuNiCoat® it is possible to build up a flawless electrolytic nickel phosphorous coating as thick as 2000 microns.

Specialists choose SuNiCoat® workable nickel phosphorous.

Turning and milling specialists all over the world choose to use SuNiCoat® for their precision optical components such as mould inserts for contact lenses, intra-ocular lenses, technical lenses for CD and DVD players and mobile phones. SuNiCoat® is also used for micro-fluid injection moulding and hot embossing components.

Advantages of SuNiCoat® Optics:

• Flawless nickel (no pitting or skip plating)

• Easy to work

• Thicknesses < 2000 micrometres

• Prolonged useful life of tools

• Savings on tool costs

• Prolonged useful life of coated components

• More than 20 years experience

• Both electroless and electrolytic nickel