Dutch United Instruments (DUI) develops instruments for form metrology of optical components. We have developed a range of NMF products, based on the famous NANOMEFOS technology of TNO (Netherlands Organization for Applied Scientific Research). NMF products bring easy, fast and accurate metrology of complex optics to your optical workshop.

The NMF products combine five characteristics into one machine, making it one tool to cover all form metrology needs in modern high-end optical manufacturing.

NMF Products

The NMF product range currently comprises four sizes: NMF350 S, NMF600 S, NMF800 S and NMF1000 S. These products are advanced 3D form metrology tools offering the advantages with respect to versatility, accuracy, speed, non-contact and ease of use for measuring any surface form from flat, sphere, asphere to freeform optics.

Versatile

Flat – Convex – Concave

Sphere – Asphere – Freeform

Off-axis, non-circular apertures

Large measurement volume

Dimension referring to the table below

Unlimited Asphere departure

Up to 5 mm PV and ± 20° for freeform

(departure from best-fit Asphere)

High point density for mid-spatial

Full surface with a few millions of points

Line scans with micrometer point spacing

Measurement uncertainty smaller than 15 nm rms

Suitable for glass, mirror, polished & ground surfaces

Fast (minutes)

A product can be aligned, measured and with result obtained in minutes

Non-contact, no damage to surface

Easy loading, alignment, programming & results processing

| Platform | Max product diameter [mm] | Max product -45° concave [mm] | Max product 45° convex [mm] | Max product 90° hemisphere [mm] | Max product height [mm] | Uncertainty [nm rms] | Footprint [mm] |

| NMF350 S | 350 | 350 | 170 | 100 | 150 | < 15 | 970 x 1600 |

| NMF600 S | 600 | 600 | 425 | 100 | 150 | < 15 | 1220 x 1750 |

| NMF800 S | 800 | 800 | 620 | 350 | 300 | < 15 | 1620 x 2150 |

| NMF1000 S | 1000 | 1000 | 820 | 350 | 300 | < 15 | 1620 x 2150 |

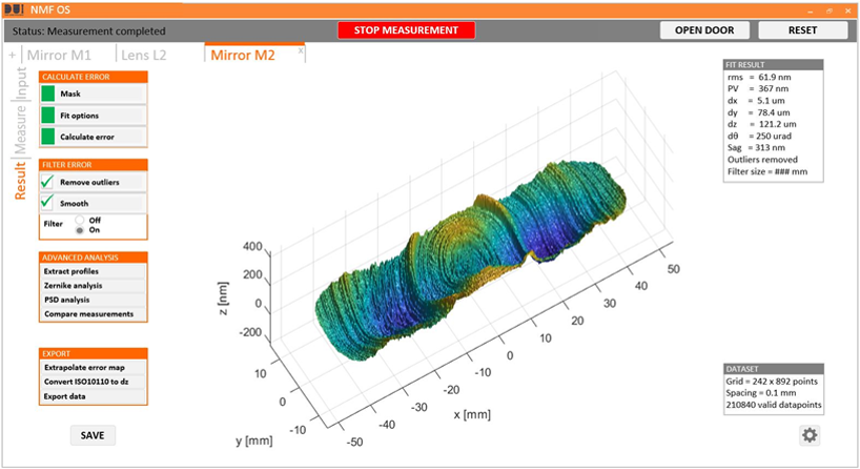

NMF Software (NMF OS)

All products are provided with our NMF OS software. This intuitive workflow based software allows you to setup and perform a measurement in a matter of minutes, calculate and analyze the results and export your data for iterative machining. DUI also offers optional software modules which enable advanced measurement input and analysis of freeform surfaces. For more details, please contact DUI.

Measurement examples: Freeform, Asphere and Sphere

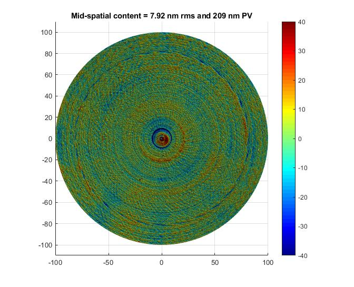

High point-density mid-spatial frequency measurement on polished and ground surfaces.

Next to polished surfaces, the optical probe of the NMF machines can also measure ground surfaces. This brings the versatility, speed and accuracy to surfaces that can normally only be measured after a first polishing step. The high measurement speed associated with the motion platform and the optical probe, translate in the ability to acquire very high-density data which is ideal for characterizing mid-spatial frequency errors in aspherical and freeform surfaces.

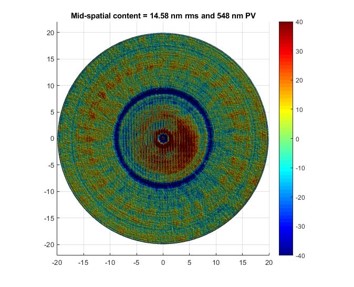

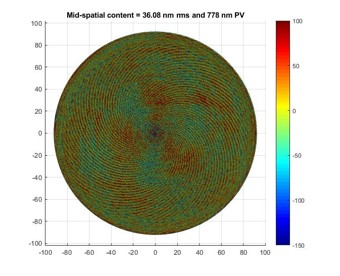

Figure (LEFT) shows the mid-spatial content of a Ø200 mm polished aspherical mirror, with Z36 Zernike coefficients subtracted. The pointspacing is 0.1 mm, it has 2k x 2k points (3.3M datapoints) and takes 18 minutes. Although only a few nm rms, the grinding residue radiating outwards from the center is still visible, as is the center defect. The machine can be used to zoom without loss of resolution, contrary to an interferometer. In Figure (MIDDLE) a subsequent measurement is shown where the measurement area was reduced to the central Ø40 mm. This measurement was done with 0.025 mm pointspacing, yields 1.6k x 1.6k points (2M datapoints) and takes less than 10 minutes. Figure (RIGHT) shows a similar measurement with 0.1 mm pointspacing on a Ø180 mm concave sphere, but this time in ground condition with Ra = 1-2 um. With Z36 removed, it shows residual grinding cusps of 36 nm rms. Being able to measure this without having to first polish the surface is obviously a valuable advantage for process optimization.

BULLETIN

What’s New at QED?

We are excited to bring you the latest edition of the QED Spotlight—your quick look at what’s new and what’s next in the world of precision optics. We’ve got some great stuff this month: a peek at how we’re growing globally, chances to learn and get hands-on with new tech, and ways to connect face-to-face.

Since our last letter, QED Technologies has acquired Dutch United Instruments (DUI), a leader in optical metrology, and their Nanomefos® technology. This addition to the QED Technologies family will establish our footprint in Europe, strengthening our global presence and expanding our capabilities in ultra-precise, non-contact metrology for freeform and aspheric optics. Want to learn more? Visit dutchunitedinstruments.com or contact your sales person.

We are thrilled to be headed to SPIE Optifab in Rochester this October! Join us at the heart of precision optics innovation, where you’ll get an up-close look at QED’s latest system upgrades, see live demos in action, and chat with our team about how we can help take your applications to the next level. Experience how QED is pushing the boundaries of what’s possible in precision manufacturing!

CHECK OUT THE LATEST VIDEOS FROM QED

50mm Scraper Alignment

A practical how-to on 50mm Wheel Scraper Alignment—a straightforward but important procedure that can have a big impact on system performance.

Script Function

QED Technologies presents a QED.net example of how to use a simple script to simplify an analysis scratchpad.

EXPANDING THE BOUNDRIES OF MRF

QED Technologies is pushing the boundaries of what’s possible in precision optics finishing. This case study explores how our 10mm MRF wheel enables access to short radius concave surfaces previously out of reach—while maintaining exceptional control over mid-spatial frequency (MSF) errors. Discover how this tool enhances flexibility and precision for manufacturers tackling complex part geometries.

DOWNLOAD THE CASE STUDY BELOW DISCOVER HOW THE 10MM WHEEL CAN ENHANCE YOUR POLISHING CAPABILITIES